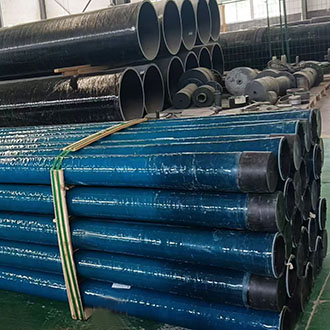

GRE pipes offer a high-performance solution for a wide range of applications due to their exceptional strength, corrosion resistance, thermal stability, and low maintenance requirements. Their versatility makes them suitable for use in the oil and gas industry, chemical processing, marine and offshore environments, power plants, water and wastewater treatment, and industrial piping.

Type:

GRE PipeMaterial:

Fiberglass + Epoxy Resin baseColor:

Resin color, can be cutomizedSize:

DN38mm-DN1000mm, can be cutomizedUse:

Oil and gas industry, chemical processing, marine and offshore environments, power plants, water and wastewater treatment, and industrial pipelinesProduct Advantages:

Lightweight, high strength, corrosion resistant and durable, easy to installconnection mode:

Threaded connection, socket bonding

Product Description

Glass Reinforced Epoxy (GRE) pipes are advanced composite pipes made from high-strength fiberglass reinforcements embedded within an epoxy resin matrix. These pipes are produced through a process called filament winding, where continuous glass fibers are impregnated with epoxy resin and wound onto a mandrel in a specific pattern. The resin is then cured to create a strong, durable, and corrosion-resistant pipe. GRE pipes are known for their excellent mechanical properties and are used in various high-performance applications.

Key Features

1.GRE pipes offer superior mechanical strength and stiffness compared to many other piping materials. This makes them suitable for high-pressure applications and environments that demand robust performance.

2.The epoxy resin used in GRE pipes provides excellent resistance to a wide range of chemicals, including acids, alkalis, and solvents. This makes GRE pipes ideal for transporting aggressive fluids and gases.

3.GRE pipes maintain their mechanical properties over a wide temperature range. They are suitable for both high-temperature and low-temperature applications, ensuring reliable performance in various conditions.

4.GRE pipes do not rust, corrode, or degrade over time, leading to lower maintenance costs and extended service life. They require minimal upkeep, making them a cost-effective solution in the long run.

5.The smooth internal surface of GRE pipes reduces friction and pressure losses during fluid flow, enhancing efficiency and reducing energy costs.

6.Despite its strength, GRE pipe is relatively lightweight compared to traditional materials such as steel and concrete. This reduces transportation and installation costs.

Packaging

Our Services

Our company has more than 40 years of production experience and professional production equipment. We can customize and produce various specifications of fiberglass reinforced epoxy conduit according to your needs. The product quality is excellent and the price is very competitive. Welcome to consult and discuss cooperation!