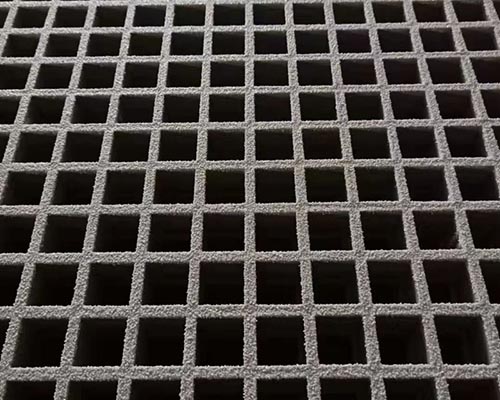

Fiberglass grating can be used for pedestrian walkways. The FRP gratings we commonly use include Molded gratings and Pultruded gratings. Today we will introduce the differences between these two types of gratings.

1.Production Process

The two types of grating are made by different machines. Their production processes are different. Molded grating is made by machines with many regular squares or long grids, while pultruded grating is made by pultrusion machines that first produce pultruded profiles and then splice the pultruded profiles.

2.Product Specifications

The commonly used height specifications of molded grilles are 25mm, 38mm and 50mm, the center hole spacing of the grid is 38mm and 50mm, the whole board size is 1220mm*3660mm and 1000mm*4040mm, and it can also be cut according to customer requirements.

Pultruded grilles are made of commonly used height specifications of 25mm, 38mm and 50mm, etc. Since they are spliced with pultruded profiles, the grid hole spacing and the size of the whole board can be customized.

FRP molded grating and FRP pultruded grating are both types of FRP grating products. They are made of high-quality glass fiber and resin. We can determine which product to choose according to different usage environments and product requirements.